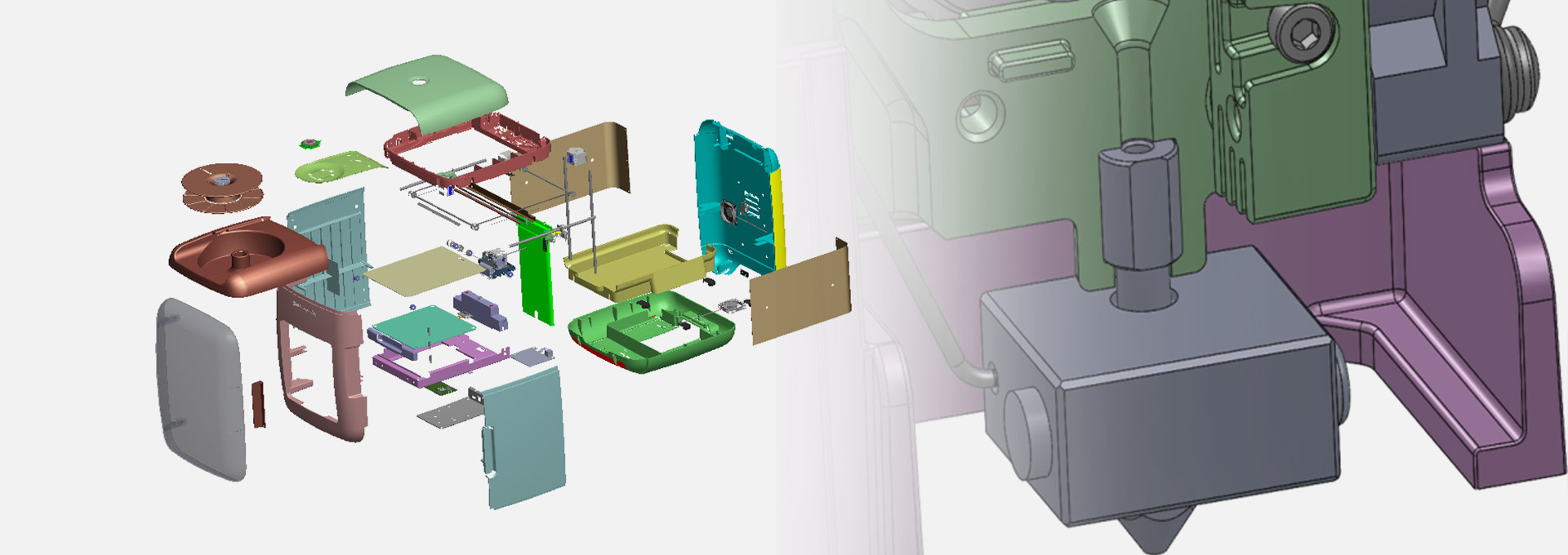

Metal molding or we called Metal injection molding (MIM) is a metalworking process by which finely-powdered metal is mixed with a measured amount of binder material to comprise a "feedstock" capable of being handled by plastic processing equipment through a process known as injection molding. The molding process allows dilated (oversized due to binder) complex parts to be shaped in a single step and in high volume. After molding, the powder-binder mixture is subjected to steps that remove the binder (debinding) and sinter densify the powders. End products are small components used in various industries and applications.

Sachimolds offers clients more efficient purchase channel and meet the demand of supply chain integration, it started to investthe wholly owned or partially hold hardware factories, thus enhancesthe ability to make more complex products, as well as widen business scope in different metal industries,which include: stamping, sand casting, die-casting, forging, CNC machining, stainless steel casting, metal injection molding.

We understand Stamping, Hot Forging, Die Casting and the post Machining processes. We use SmartStart™ DFM review to address possible problematic areas about proper draft angle, radii, wall thicknesses and machine stock. We also employ Magmasoft, an extremely accurate metal casting simulator, to optimize gating and shot profile, reduce porosity and air entrapment of the mold design.